产品分类

Contactus

86-312-8968819

- Baoding, Hebei, China

- 86-312-8968819

- 86-312-8968919

- lifting@trarms.cn

- 810702939

合成纤维绳吊带及末端件

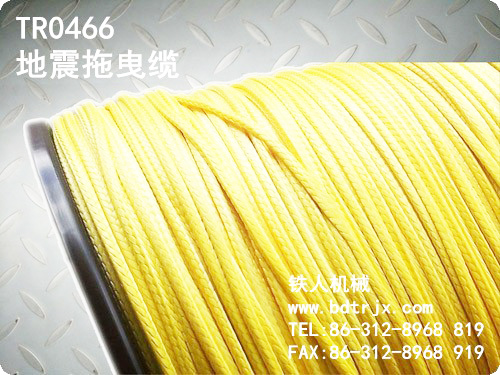

TR0466 Tow Rope

已知的可靠性和领先的性能

与迪尼玛由海洋地震绳索® SK78更薄,更强烈,更安全-他们更容易精确定位传感器。

更薄更轻的绳索减少阻力

伸长率低可以使传感器精确定位

卓越的抗磨损性,用于电缆保护

DYNEEMA® HIGH PERFORMANCE FIBERS ARE USED FOR TOWING LINES IN NEW OCEAN-GOING VESSELS

URMOND (NL), 22 September 2010 - The seismic research vessels “Ramform Sovereign” and “Ramform Sterling” are equipped with towing and spreader ropes made from Dyneema® ultra-high molecular weight polyethylene fiber. These are among the latest in a large fleet operated by Petroleum Geo-Services (PGS), one of the world’s leading offshore services companies. The Ramform Sovereign and Ramform Sterling each deploy up to 20 seismic streamers.

PGS specializes in “reflection seismology” services, using specially equipped vessels fitted with a series of tethered hydrophone arrays that can reach lengths of up to 12 kilometers. One of its competitive advantages is its ability to achieve higher-resolution data than its competitors, by towing a denser array of sensors. To help reduce the weight of these arrays, PGS has specified UHMWPE fiber of DSM Dyneema for a wide range of towing and other ropes, for use on vessels throughout its fleet. Applications include superwide towing rope, streamer spread ropes, various bridling systems and fabricated multiple splice connections.

“Ropes made with Dyneema® are very strong, light weight, and resistant to harsh environments,” says Brad Bertsch, Mechanical Supervisor at PGS. “They can be easily spliced, have very little creep, have very low elasticity and are resistant to chemicals and corrosion. And ropes made with Dyneema® are easy on our ships’ equipment, sheaves, and winches.”

Industry reports show that towing lines made with Dyneema® fiber require replacement only every two years, whereas steel wire ropes used in seismic applications typically have a lifetime of just four to five months.

Safety in use provides a further, critical advantage for ropes made with Dyneema®. With extremely long lines under very high tension, steel lines always carry the risk of “snap back” if a wire breaks. Dyneema® helps to virtually eliminate this threat due its low elongation qualities, a factor that also aids in the precise placement of lines and equipment. Resistance to tension and bending fatigue weigh further in favor of Dyneema®.

Dyneema® is less dense than water. Bertsch says the buoyancy that this provides is another major advantage over steel cable in seaborne applications. Furthermore, the low weight and low diameter, of the ropes made with Dyneema® played an important part in PGS being able to fit greater lengths of rope onto existing winches, and also in controlling costs, such as those associated with fuel usage, that are impacted by towing weight.

“The use of rope made with Dyneema® in the Seismic industry with PGS is still growing,“ says Bertsch, “and there are always new ideas coming out where Dyneema® can be used one way or another. PGS is committed to continual technical improvement, and lightweight Dyneema® falls clearly into that category.“

“We started adopting this technology in 1994.The superior performance of the ropes, their greater safety in operation and their extended lifetime compared to steel wire make Dyneema® fiber an obvious choice for rigging our fleet.”

Reader Enquiries:

DSM Dyneema

Urmonderbaan 22

6167 RD Geleen

Editorial - Company

Tel: +31 46 476 6466

Fax: +31 46 476 7915

Email: press.dyneema@dsm.com

Web: www.dyneema.com

Notes For Editors:

About DSM Dyneema

DSM Dyneema is the inventor and manufacturer of Dyneema®, the world’s strongest fiber™. Dyneema® is an ultra strong polyethylene fiber that offers maximum strength combined with minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid fibers, both on weight for weight basis. Dyneema® floats on water and is extremely durable and resistant to moisture, UV light and chemicals. The applications are therefore more or less unlimited. Dyneema® is an important component in ropes, cables and nets in the fishing, shipping and offshore industries. Dyneema® is also used in safety gloves for the metalworking industry and in fine yarns for applications in sporting goods and the medical sector. In addition, Dyneema® is also used in bullet resistant armor and clothing for police and military personnel. Dyneema® is produced in Heerlen (The Netherlands), Flaach (Switzerland) and in Greenville, North Carolina (U.S.A.). DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan. Further information on DSM Dyneema is available at www.dyneema.com and www.offshore.dyneema.com.

DSM – the Life Sciences and Materials Sciences Company

Royal DSM N.V. creates solutions that nourish, protect and improve performance. Its end markets include human and animal nutrition and health, personal care, pharmaceuticals, automotive, coatings and paint, electrical and electronics, life protection and housing. DSM manages its business with a focus on the triple bottom line of economic performance, environmental quality and social responsibility, which it pursues simultaneously and in parallel. DSM has annual net sales of about € 8 billion and employs some 22,700 people worldwide. The company is headquartered in the Netherlands, with locations on five continents. DSM is listed on Euronext Amsterdam. More information: www.dsm.com.

Dyneema® and Dyneema®, the world's strongest fiber™ are trademarks of Royal DSM. Use of these trademarks is prohibited unless strictly authorized.

All other trademarks are the property of their respective owners.

图片由Fugro-Geoteam AS提供

新船在边境地区寻找工作,特别是北极和深水

2012年“地震船调查”发现船舶数量比上年增加8艘,但其中很大一部分是由于船舶运营商的报告越来越多。扣除现有但新报告的六艘船舶实际净增加额为三年同比。

值得关注的一个趋势是针对全球更加困难和危险区域的船舶,包括北极和更深的水域。另一个是越来越多地使用现场地震和海底节点装置来增加地球物理对油藏管理的洞察力。

CGGVeritas说,去年深水已经进入了国际业务,特别是在东非和西非。

从2006年到今年初,PGS海洋地球物理公司在平方公里的基础上对地震增长的需求增长了大约70%。其中,3D比整体市场增长更快。这是因为勘探变得越来越困难,水深越深,目标越深,地质学越复杂,环境越恶劣,这些都需要更高的数据质量。

Polarcus关注市场,预计今年勘探和生产支出将在15-20%的范围内增长。因此,2012年船队净增长率约为3%。需求最强劲的地区包括欧洲西北部的北极,包括格陵兰岛在内的北极,以及美国,巴西和西非的深水区域。

DMNG正致力于与在东半球工作的石油公司建立关系。为此,ISO和Achilles认证已经实现并且全职HSE。管理团队的标准和做法不断得到审查和改进。

SMNG正在用其3D Akademik Nemchinov探索里海。里海合同完成后,该船将被运往巴库港进行定期维修。在开始对里海Rakushechnoye结构的Geo能源集团进行3D调查之前,该船在波兰采用新型发动机升级。

进入里海本身就是一个项目。唯一的路线是通过Don-Volga运河系统,最大深度低于Akademik Nemchinov的吃水深度。为了准备旅程做了大的临时改动。该船的吃水深度从5.6米降至3.5米(18.4米至11.4米)。桅杆和地震设备被拆除,船只放在九个浮筒上。

2011年记录了一些业务举措。建立GeoRXT的决定源自RXT管理层的战略审查,以实现其巴西业务的价值。作为合资协议的一部分,Georadar已经向GeoRXT投入了2000万美元,而RXT已经收到1000万美元的现金对价。 GeoRXT最初将重点放在对南美,安哥拉和一些中东地区OBC地震勘测工作的预期需求上。 RXT集团将把活动集中在北海,墨西哥湾和西非,在那里它有高分辨率多组分数据的记录。

高质量数据在最佳评估和发现发现方面起着关键作用,降低钻井新井的风险。同样,高质量地震是石油公司阻止成熟油田产量下降的关键工具。高清晰度3D海底地震(HDOBC)正在成为牵引拖缆采集的强有力竞争对手,需要进行评估和生产钻井的高清晰度勘测。 RXT的HDOBC在这些受阻和具有挑战性的环境中提供数据。

2011年末,SeaBird公司达成协议,将Fugro OBN Technologies AS和Seabed Navigation Co. Ltd.的股份出售给Fugro。这导致Fugro现在持有Fugro OBN和海底导航系统的100%。

BGP最近的研发主要集中在高密度地震勘探,宽方位采集,复杂结构成像,3C / 3D VSP,3C / 3D地震以及地层储层研究。该公司也开始开发自己的地震记录系统。

BGP称其拥有中国最大的地球物理和地质研发中心。该研究涵盖了所有的地球物理学和地质学,并以高阶分裂迁移和多项式拟合而着称。

在离岸方面,CGGVeritas通过Sercel产品提供纯粹的地球物理服务和设备。 Sercel拥有陆地和海洋地球物理设备,包括集成电子记录系统,电缆,陆地,海底和井下传感器,拖缆,海上地震源和振动器。其地球物理服务涵盖采集,数据处理和成像以及油藏管理。通过Hampson-Russell软件与服务,CGGVeritas提供地球物理解释软件和油藏描述。

CGGVeritas最近升级了它的19个vess地震车队 已知的可靠性和领先的性能

与迪尼玛由海洋地震绳索® SK78更薄,更强烈,更安全-他们更容易精确定位传感器。

更薄更轻的绳索减少阻力

伸长率低可以使传感器精确定位

卓越的抗磨损性,用于电缆保护

DYNEEMA® HIGH PERFORMANCE FIBERS ARE USED FOR TOWING LINES IN NEW OCEAN-GOING VESSELS

URMOND (NL), 22 September 2010 - The seismic research vessels “Ramform Sovereign” and “Ramform Sterling” are equipped with towing and spreader ropes made from Dyneema® ultra-high molecular weight polyethylene fiber. These are among the latest in a large fleet operated by Petroleum Geo-Services (PGS), one of the world’s leading offshore services companies. The Ramform Sovereign and Ramform Sterling each deploy up to 20 seismic streamers.

PGS specializes in “reflection seismology” services, using specially equipped vessels fitted with a series of tethered hydrophone arrays that can reach lengths of up to 12 kilometers. One of its competitive advantages is its ability to achieve higher-resolution data than its competitors, by towing a denser array of sensors. To help reduce the weight of these arrays, PGS has specified UHMWPE fiber of DSM Dyneema for a wide range of towing and other ropes, for use on vessels throughout its fleet. Applications include superwide towing rope, streamer spread ropes, various bridling systems and fabricated multiple splice connections.

“Ropes made with Dyneema® are very strong, light weight, and resistant to harsh environments,” says Brad Bertsch, Mechanical Supervisor at PGS. “They can be easily spliced, have very little creep, have very low elasticity and are resistant to chemicals and corrosion. And ropes made with Dyneema® are easy on our ships’ equipment, sheaves, and winches.”

Industry reports show that towing lines made with Dyneema® fiber require replacement only every two years, whereas steel wire ropes used in seismic applications typically have a lifetime of just four to five months.

Safety in use provides a further, critical advantage for ropes made with Dyneema®. With extremely long lines under very high tension, steel lines always carry the risk of “snap back” if a wire breaks. Dyneema® helps to virtually eliminate this threat due its low elongation qualities, a factor that also aids in the precise placement of lines and equipment. Resistance to tension and bending fatigue weigh further in favor of Dyneema®.

Dyneema® is less dense than water. Bertsch says the buoyancy that this provides is another major advantage over steel cable in seaborne applications. Furthermore, the low weight and low diameter, of the ropes made with Dyneema® played an important part in PGS being able to fit greater lengths of rope onto existing winches, and also in controlling costs, such as those associated with fuel usage, that are impacted by towing weight.

“The use of rope made with Dyneema® in the Seismic industry with PGS is still growing,“ says Bertsch, “and there are always new ideas coming out where Dyneema® can be used one way or another. PGS is committed to continual technical improvement, and lightweight Dyneema® falls clearly into that category.“

“We started adopting this technology in 1994.The superior performance of the ropes, their greater safety in operation and their extended lifetime compared to steel wire make Dyneema® fiber an obvious choice for rigging our fleet.”

Reader Enquiries:

DSM Dyneema

Urmonderbaan 22

6167 RD Geleen

Editorial - Company

Tel: +31 46 476 6466

Fax: +31 46 476 7915

Email: press.dyneema@dsm.com

Web: www.dyneema.com

Notes For Editors:

About DSM Dyneema

DSM Dyneema is the inventor and manufacturer of Dyneema®, the world’s strongest fiber™. Dyneema® is an ultra strong polyethylene fiber that offers maximum strength combined with minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid fibers, both on weight for weight basis. Dyneema® floats on water and is extremely durable and resistant to moisture, UV light and chemicals. The applications are therefore more or less unlimited. Dyneema® is an important component in ropes, cables and nets in the fishing, shipping and offshore industries. Dyneema® is also used in safety gloves for the metalworking industry and in fine yarns for applications in sporting goods and the medical sector. In addition, Dyneema® is also used in bullet resistant armor and clothing for police and military personnel. Dyneema® is produced in Heerlen (The Netherlands), Flaach (Switzerland) and in Greenville, North Carolina (U.S.A.). DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan. Further information on DSM Dyneema is available at www.dyneema.com and www.offshore.dyneema.com.

DSM – the Life Sciences and Materials Sciences Company

Royal DSM N.V. creates solutions that nourish, protect and improve performance. Its end markets include human and animal nutrition and health, personal care, pharmaceuticals, automotive, coatings and paint, electrical and electronics, life protection and housing. DSM manages its business with a focus on the triple bottom line of economic performance, environmental quality and social responsibility, which it pursues simultaneously and in parallel. DSM has annual net sales of about € 8 billion and employs some 22,700 people worldwide. The company is headquartered in the Netherlands, with locations on five continents. DSM is listed on Euronext Amsterdam. More information: www.dsm.com.

Dyneema® and Dyneema®, the world's strongest fiber™ are trademarks of Royal DSM. Use of these trademarks is prohibited unless strictly authorized.

All other trademarks are the property of their respective owners.

图片由Fugro-Geoteam AS提供

新船在边境地区寻找工作,特别是北极和深水

2012年“地震船调查”发现船舶数量比上年增加8艘,但其中很大一部分是由于船舶运营商的报告越来越多。扣除现有但新报告的六艘船舶实际净增加额为三年同比。

值得关注的一个趋势是针对全球更加困难和危险区域的船舶,包括北极和更深的水域。另一个是越来越多地使用现场地震和海底节点装置来增加地球物理对油藏管理的洞察力。

CGGVeritas说,去年深水已经进入了国际业务,特别是在东非和西非。

从2006年到今年初,PGS海洋地球物理公司在平方公里的基础上对地震增长的需求增长了大约70%。其中,3D比整体市场增长更快。这是因为勘探变得越来越困难,水深越深,目标越深,地质学越复杂,环境越恶劣,这些都需要更高的数据质量。

Polarcus关注市场,预计今年勘探和生产支出将在15-20%的范围内增长。因此,2012年船队净增长率约为3%。需求最强劲的地区包括欧洲西北部的北极,包括格陵兰岛在内的北极,以及美国,巴西和西非的深水区域。

DMNG正致力于与在东半球工作的石油公司建立关系。为此,ISO和Achilles认证已经实现并且全职HSE。管理团队的标准和做法不断得到审查和改进。

SMNG正在用其3D Akademik Nemchinov探索里海。里海合同完成后,该船将被运往巴库港进行定期维修。在开始对里海Rakushechnoye结构的Geo能源集团进行3D调查之前,该船在波兰采用新型发动机升级。

进入里海本身就是一个项目。唯一的路线是通过Don-Volga运河系统,最大深度低于Akademik Nemchinov的吃水深度。为了准备旅程做了大的临时改动。该船的吃水深度从5.6米降至3.5米(18.4米至11.4米)。桅杆和地震设备被拆除,船只放在九个浮筒上。

2011年记录了一些业务举措。建立GeoRXT的决定源自RXT管理层的战略审查,以实现其巴西业务的价值。作为合资协议的一部分,Georadar已经向GeoRXT投入了2000万美元,而RXT已经收到1000万美元的现金对价。 GeoRXT最初将重点放在对南美,安哥拉和一些中东地区OBC地震勘测工作的预期需求上。 RXT集团将把活动集中在北海,墨西哥湾和西非,在那里它有高分辨率多组分数据的记录。

高质量数据在最佳评估和发现发现方面起着关键作用,降低钻井新井的风险。同样,高质量地震是石油公司阻止成熟油田产量下降的关键工具。高清晰度3D海底地震(HDOBC)正在成为牵引拖缆采集的强有力竞争对手,需要进行评估和生产钻井的高清晰度勘测。 RXT的HDOBC在这些受阻和具有挑战性的环境中提供数据。

2011年末,SeaBird公司达成协议,将Fugro OBN Technologies AS和Seabed Navigation Co. Ltd.的股份出售给Fugro。这导致Fugro现在持有Fugro OBN和海底导航系统的100%。

BGP最近的研发主要集中在高密度地震勘探,宽方位采集,复杂结构成像,3C / 3D VSP,3C / 3D地震以及地层储层研究。该公司也开始开发自己的地震记录系统。

BGP称其拥有中国最大的地球物理和地质研发中心。该研究涵盖了所有的地球物理学和地质学,并以高阶分裂迁移和多项式拟合而着称。

在离岸方面,CGGVeritas通过Sercel产品提供纯粹的地球物理服务和设备。 Sercel拥有陆地和海洋地球物理设备,包括集成电子记录系统,电缆,陆地,海底和井下传感器,拖缆,海上地震源和振动器。其地球物理服务涵盖采集,数据处理和成像以及油藏管理。通过Hampson-Russell软件与服务,CGGVeritas提供地球物理解释软件和油藏描述。

CGGVeritas最近升级了它的19个vess地震车队

与迪尼玛由海洋地震绳索® SK78更薄,更强烈,更安全-他们更容易精确定位传感器。

更薄更轻的绳索减少阻力

伸长率低可以使传感器精确定位

卓越的抗磨损性,用于电缆保护

DYNEEMA® HIGH PERFORMANCE FIBERS ARE USED FOR TOWING LINES IN NEW OCEAN-GOING VESSELS

URMOND (NL), 22 September 2010 - The seismic research vessels “Ramform Sovereign” and “Ramform Sterling” are equipped with towing and spreader ropes made from Dyneema® ultra-high molecular weight polyethylene fiber. These are among the latest in a large fleet operated by Petroleum Geo-Services (PGS), one of the world’s leading offshore services companies. The Ramform Sovereign and Ramform Sterling each deploy up to 20 seismic streamers.

PGS specializes in “reflection seismology” services, using specially equipped vessels fitted with a series of tethered hydrophone arrays that can reach lengths of up to 12 kilometers. One of its competitive advantages is its ability to achieve higher-resolution data than its competitors, by towing a denser array of sensors. To help reduce the weight of these arrays, PGS has specified UHMWPE fiber of DSM Dyneema for a wide range of towing and other ropes, for use on vessels throughout its fleet. Applications include superwide towing rope, streamer spread ropes, various bridling systems and fabricated multiple splice connections.

“Ropes made with Dyneema® are very strong, light weight, and resistant to harsh environments,” says Brad Bertsch, Mechanical Supervisor at PGS. “They can be easily spliced, have very little creep, have very low elasticity and are resistant to chemicals and corrosion. And ropes made with Dyneema® are easy on our ships’ equipment, sheaves, and winches.”

Industry reports show that towing lines made with Dyneema® fiber require replacement only every two years, whereas steel wire ropes used in seismic applications typically have a lifetime of just four to five months.

Safety in use provides a further, critical advantage for ropes made with Dyneema®. With extremely long lines under very high tension, steel lines always carry the risk of “snap back” if a wire breaks. Dyneema® helps to virtually eliminate this threat due its low elongation qualities, a factor that also aids in the precise placement of lines and equipment. Resistance to tension and bending fatigue weigh further in favor of Dyneema®.

Dyneema® is less dense than water. Bertsch says the buoyancy that this provides is another major advantage over steel cable in seaborne applications. Furthermore, the low weight and low diameter, of the ropes made with Dyneema® played an important part in PGS being able to fit greater lengths of rope onto existing winches, and also in controlling costs, such as those associated with fuel usage, that are impacted by towing weight.

“The use of rope made with Dyneema® in the Seismic industry with PGS is still growing,“ says Bertsch, “and there are always new ideas coming out where Dyneema® can be used one way or another. PGS is committed to continual technical improvement, and lightweight Dyneema® falls clearly into that category.“

“We started adopting this technology in 1994.The superior performance of the ropes, their greater safety in operation and their extended lifetime compared to steel wire make Dyneema® fiber an obvious choice for rigging our fleet.”

Reader Enquiries:

DSM Dyneema

Urmonderbaan 22

6167 RD Geleen

Editorial - Company

Tel: +31 46 476 6466

Fax: +31 46 476 7915

Email: press.dyneema@dsm.com

Web: www.dyneema.com

Notes For Editors:

About DSM Dyneema

DSM Dyneema is the inventor and manufacturer of Dyneema®, the world’s strongest fiber™. Dyneema® is an ultra strong polyethylene fiber that offers maximum strength combined with minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid fibers, both on weight for weight basis. Dyneema® floats on water and is extremely durable and resistant to moisture, UV light and chemicals. The applications are therefore more or less unlimited. Dyneema® is an important component in ropes, cables and nets in the fishing, shipping and offshore industries. Dyneema® is also used in safety gloves for the metalworking industry and in fine yarns for applications in sporting goods and the medical sector. In addition, Dyneema® is also used in bullet resistant armor and clothing for police and military personnel. Dyneema® is produced in Heerlen (The Netherlands), Flaach (Switzerland) and in Greenville, North Carolina (U.S.A.). DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan. Further information on DSM Dyneema is available at www.dyneema.com and www.offshore.dyneema.com.

DSM – the Life Sciences and Materials Sciences Company

Royal DSM N.V. creates solutions that nourish, protect and improve performance. Its end markets include human and animal nutrition and health, personal care, pharmaceuticals, automotive, coatings and paint, electrical and electronics, life protection and housing. DSM manages its business with a focus on the triple bottom line of economic performance, environmental quality and social responsibility, which it pursues simultaneously and in parallel. DSM has annual net sales of about € 8 billion and employs some 22,700 people worldwide. The company is headquartered in the Netherlands, with locations on five continents. DSM is listed on Euronext Amsterdam. More information: www.dsm.com.

Dyneema® and Dyneema®, the world's strongest fiber™ are trademarks of Royal DSM. Use of these trademarks is prohibited unless strictly authorized.

All other trademarks are the property of their respective owners.

图片由Fugro-Geoteam AS提供

新船在边境地区寻找工作,特别是北极和深水

2012年“地震船调查”发现船舶数量比上年增加8艘,但其中很大一部分是由于船舶运营商的报告越来越多。扣除现有但新报告的六艘船舶实际净增加额为三年同比。

值得关注的一个趋势是针对全球更加困难和危险区域的船舶,包括北极和更深的水域。另一个是越来越多地使用现场地震和海底节点装置来增加地球物理对油藏管理的洞察力。

CGGVeritas说,去年深水已经进入了国际业务,特别是在东非和西非。

从2006年到今年初,PGS海洋地球物理公司在平方公里的基础上对地震增长的需求增长了大约70%。其中,3D比整体市场增长更快。这是因为勘探变得越来越困难,水深越深,目标越深,地质学越复杂,环境越恶劣,这些都需要更高的数据质量。

Polarcus关注市场,预计今年勘探和生产支出将在15-20%的范围内增长。因此,2012年船队净增长率约为3%。需求最强劲的地区包括欧洲西北部的北极,包括格陵兰岛在内的北极,以及美国,巴西和西非的深水区域。

DMNG正致力于与在东半球工作的石油公司建立关系。为此,ISO和Achilles认证已经实现并且全职HSE。管理团队的标准和做法不断得到审查和改进。

SMNG正在用其3D Akademik Nemchinov探索里海。里海合同完成后,该船将被运往巴库港进行定期维修。在开始对里海Rakushechnoye结构的Geo能源集团进行3D调查之前,该船在波兰采用新型发动机升级。

进入里海本身就是一个项目。唯一的路线是通过Don-Volga运河系统,最大深度低于Akademik Nemchinov的吃水深度。为了准备旅程做了大的临时改动。该船的吃水深度从5.6米降至3.5米(18.4米至11.4米)。桅杆和地震设备被拆除,船只放在九个浮筒上。

2011年记录了一些业务举措。建立GeoRXT的决定源自RXT管理层的战略审查,以实现其巴西业务的价值。作为合资协议的一部分,Georadar已经向GeoRXT投入了2000万美元,而RXT已经收到1000万美元的现金对价。 GeoRXT最初将重点放在对南美,安哥拉和一些中东地区OBC地震勘测工作的预期需求上。 RXT集团将把活动集中在北海,墨西哥湾和西非,在那里它有高分辨率多组分数据的记录。

高质量数据在最佳评估和发现发现方面起着关键作用,降低钻井新井的风险。同样,高质量地震是石油公司阻止成熟油田产量下降的关键工具。高清晰度3D海底地震(HDOBC)正在成为牵引拖缆采集的强有力竞争对手,需要进行评估和生产钻井的高清晰度勘测。 RXT的HDOBC在这些受阻和具有挑战性的环境中提供数据。

2011年末,SeaBird公司达成协议,将Fugro OBN Technologies AS和Seabed Navigation Co. Ltd.的股份出售给Fugro。这导致Fugro现在持有Fugro OBN和海底导航系统的100%。

BGP最近的研发主要集中在高密度地震勘探,宽方位采集,复杂结构成像,3C / 3D VSP,3C / 3D地震以及地层储层研究。该公司也开始开发自己的地震记录系统。

BGP称其拥有中国最大的地球物理和地质研发中心。该研究涵盖了所有的地球物理学和地质学,并以高阶分裂迁移和多项式拟合而着称。

在离岸方面,CGGVeritas通过Sercel产品提供纯粹的地球物理服务和设备。 Sercel拥有陆地和海洋地球物理设备,包括集成电子记录系统,电缆,陆地,海底和井下传感器,拖缆,海上地震源和振动器。其地球物理服务涵盖采集,数据处理和成像以及油藏管理。通过Hampson-Russell软件与服务,CGGVeritas提供地球物理解释软件和油藏描述。

CGGVeritas最近升级了它的19个vess地震车队 已知的可靠性和领先的性能

与迪尼玛由海洋地震绳索® SK78更薄,更强烈,更安全-他们更容易精确定位传感器。

更薄更轻的绳索减少阻力

伸长率低可以使传感器精确定位

卓越的抗磨损性,用于电缆保护

DYNEEMA® HIGH PERFORMANCE FIBERS ARE USED FOR TOWING LINES IN NEW OCEAN-GOING VESSELS

URMOND (NL), 22 September 2010 - The seismic research vessels “Ramform Sovereign” and “Ramform Sterling” are equipped with towing and spreader ropes made from Dyneema® ultra-high molecular weight polyethylene fiber. These are among the latest in a large fleet operated by Petroleum Geo-Services (PGS), one of the world’s leading offshore services companies. The Ramform Sovereign and Ramform Sterling each deploy up to 20 seismic streamers.

PGS specializes in “reflection seismology” services, using specially equipped vessels fitted with a series of tethered hydrophone arrays that can reach lengths of up to 12 kilometers. One of its competitive advantages is its ability to achieve higher-resolution data than its competitors, by towing a denser array of sensors. To help reduce the weight of these arrays, PGS has specified UHMWPE fiber of DSM Dyneema for a wide range of towing and other ropes, for use on vessels throughout its fleet. Applications include superwide towing rope, streamer spread ropes, various bridling systems and fabricated multiple splice connections.

“Ropes made with Dyneema® are very strong, light weight, and resistant to harsh environments,” says Brad Bertsch, Mechanical Supervisor at PGS. “They can be easily spliced, have very little creep, have very low elasticity and are resistant to chemicals and corrosion. And ropes made with Dyneema® are easy on our ships’ equipment, sheaves, and winches.”

Industry reports show that towing lines made with Dyneema® fiber require replacement only every two years, whereas steel wire ropes used in seismic applications typically have a lifetime of just four to five months.

Safety in use provides a further, critical advantage for ropes made with Dyneema®. With extremely long lines under very high tension, steel lines always carry the risk of “snap back” if a wire breaks. Dyneema® helps to virtually eliminate this threat due its low elongation qualities, a factor that also aids in the precise placement of lines and equipment. Resistance to tension and bending fatigue weigh further in favor of Dyneema®.

Dyneema® is less dense than water. Bertsch says the buoyancy that this provides is another major advantage over steel cable in seaborne applications. Furthermore, the low weight and low diameter, of the ropes made with Dyneema® played an important part in PGS being able to fit greater lengths of rope onto existing winches, and also in controlling costs, such as those associated with fuel usage, that are impacted by towing weight.

“The use of rope made with Dyneema® in the Seismic industry with PGS is still growing,“ says Bertsch, “and there are always new ideas coming out where Dyneema® can be used one way or another. PGS is committed to continual technical improvement, and lightweight Dyneema® falls clearly into that category.“

“We started adopting this technology in 1994.The superior performance of the ropes, their greater safety in operation and their extended lifetime compared to steel wire make Dyneema® fiber an obvious choice for rigging our fleet.”

Reader Enquiries:

DSM Dyneema

Urmonderbaan 22

6167 RD Geleen

Editorial - Company

Tel: +31 46 476 6466

Fax: +31 46 476 7915

Email: press.dyneema@dsm.com

Web: www.dyneema.com

Notes For Editors:

About DSM Dyneema

DSM Dyneema is the inventor and manufacturer of Dyneema®, the world’s strongest fiber™. Dyneema® is an ultra strong polyethylene fiber that offers maximum strength combined with minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid fibers, both on weight for weight basis. Dyneema® floats on water and is extremely durable and resistant to moisture, UV light and chemicals. The applications are therefore more or less unlimited. Dyneema® is an important component in ropes, cables and nets in the fishing, shipping and offshore industries. Dyneema® is also used in safety gloves for the metalworking industry and in fine yarns for applications in sporting goods and the medical sector. In addition, Dyneema® is also used in bullet resistant armor and clothing for police and military personnel. Dyneema® is produced in Heerlen (The Netherlands), Flaach (Switzerland) and in Greenville, North Carolina (U.S.A.). DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan. Further information on DSM Dyneema is available at www.dyneema.com and www.offshore.dyneema.com.

DSM – the Life Sciences and Materials Sciences Company

Royal DSM N.V. creates solutions that nourish, protect and improve performance. Its end markets include human and animal nutrition and health, personal care, pharmaceuticals, automotive, coatings and paint, electrical and electronics, life protection and housing. DSM manages its business with a focus on the triple bottom line of economic performance, environmental quality and social responsibility, which it pursues simultaneously and in parallel. DSM has annual net sales of about € 8 billion and employs some 22,700 people worldwide. The company is headquartered in the Netherlands, with locations on five continents. DSM is listed on Euronext Amsterdam. More information: www.dsm.com.

Dyneema® and Dyneema®, the world's strongest fiber™ are trademarks of Royal DSM. Use of these trademarks is prohibited unless strictly authorized.

All other trademarks are the property of their respective owners.

图片由Fugro-Geoteam AS提供

新船在边境地区寻找工作,特别是北极和深水

2012年“地震船调查”发现船舶数量比上年增加8艘,但其中很大一部分是由于船舶运营商的报告越来越多。扣除现有但新报告的六艘船舶实际净增加额为三年同比。

值得关注的一个趋势是针对全球更加困难和危险区域的船舶,包括北极和更深的水域。另一个是越来越多地使用现场地震和海底节点装置来增加地球物理对油藏管理的洞察力。

CGGVeritas说,去年深水已经进入了国际业务,特别是在东非和西非。

从2006年到今年初,PGS海洋地球物理公司在平方公里的基础上对地震增长的需求增长了大约70%。其中,3D比整体市场增长更快。这是因为勘探变得越来越困难,水深越深,目标越深,地质学越复杂,环境越恶劣,这些都需要更高的数据质量。

Polarcus关注市场,预计今年勘探和生产支出将在15-20%的范围内增长。因此,2012年船队净增长率约为3%。需求最强劲的地区包括欧洲西北部的北极,包括格陵兰岛在内的北极,以及美国,巴西和西非的深水区域。

DMNG正致力于与在东半球工作的石油公司建立关系。为此,ISO和Achilles认证已经实现并且全职HSE。管理团队的标准和做法不断得到审查和改进。

SMNG正在用其3D Akademik Nemchinov探索里海。里海合同完成后,该船将被运往巴库港进行定期维修。在开始对里海Rakushechnoye结构的Geo能源集团进行3D调查之前,该船在波兰采用新型发动机升级。

进入里海本身就是一个项目。唯一的路线是通过Don-Volga运河系统,最大深度低于Akademik Nemchinov的吃水深度。为了准备旅程做了大的临时改动。该船的吃水深度从5.6米降至3.5米(18.4米至11.4米)。桅杆和地震设备被拆除,船只放在九个浮筒上。

2011年记录了一些业务举措。建立GeoRXT的决定源自RXT管理层的战略审查,以实现其巴西业务的价值。作为合资协议的一部分,Georadar已经向GeoRXT投入了2000万美元,而RXT已经收到1000万美元的现金对价。 GeoRXT最初将重点放在对南美,安哥拉和一些中东地区OBC地震勘测工作的预期需求上。 RXT集团将把活动集中在北海,墨西哥湾和西非,在那里它有高分辨率多组分数据的记录。

高质量数据在最佳评估和发现发现方面起着关键作用,降低钻井新井的风险。同样,高质量地震是石油公司阻止成熟油田产量下降的关键工具。高清晰度3D海底地震(HDOBC)正在成为牵引拖缆采集的强有力竞争对手,需要进行评估和生产钻井的高清晰度勘测。 RXT的HDOBC在这些受阻和具有挑战性的环境中提供数据。

2011年末,SeaBird公司达成协议,将Fugro OBN Technologies AS和Seabed Navigation Co. Ltd.的股份出售给Fugro。这导致Fugro现在持有Fugro OBN和海底导航系统的100%。

BGP最近的研发主要集中在高密度地震勘探,宽方位采集,复杂结构成像,3C / 3D VSP,3C / 3D地震以及地层储层研究。该公司也开始开发自己的地震记录系统。

BGP称其拥有中国最大的地球物理和地质研发中心。该研究涵盖了所有的地球物理学和地质学,并以高阶分裂迁移和多项式拟合而着称。

在离岸方面,CGGVeritas通过Sercel产品提供纯粹的地球物理服务和设备。 Sercel拥有陆地和海洋地球物理设备,包括集成电子记录系统,电缆,陆地,海底和井下传感器,拖缆,海上地震源和振动器。其地球物理服务涵盖采集,数据处理和成像以及油藏管理。通过Hampson-Russell软件与服务,CGGVeritas提供地球物理解释软件和油藏描述。

CGGVeritas最近升级了它的19个vess地震车队

中文版

中文版 English

English